Fused Welding Flux for Low Alloy Steel Structure, Ship, Boiler

Basic Info

Model No.: welding flux

Product Description

Model NO.: Welding Flux

pH: Acidic

Melting Point: >600℃

Function: Protect Weld Metal

Manufacturing Method: Smelted

Color: Red Brown,Light Yellow

Current: AC or DC

Payment: Tt or LC

Packings: Paper Bag or Pallet

Weld: Ship,Boiler

Specification: hj431

state: Solid

Type: Inorganic

Chemical Composition: SiO₂=10%-30%

Application: Submerged-arc Welding

Kind: Fused Welding Flux

Grain Size: 8-40meshes

Suitable: Low Carbon Low Alloy Steel

Delivery: 15-20 Days

Port: Qingdao

Trademark: trustworthy

Origin: Shandong China

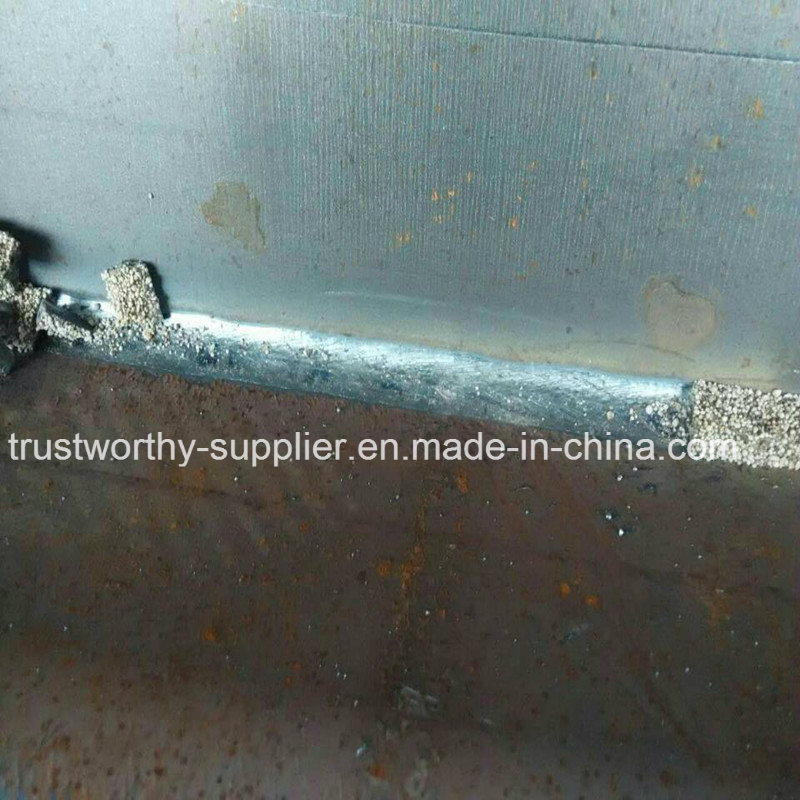

Submerged arc welding flux hj431

| Fit | GB/T5293-1999 | F4A3-H08A | F5A2-H08MnA |

| Equivalent to | AWS-A5.17 | F6A2-EL12 | F7A3-EM12K |

1.it is a kind of high manganese and silicon, low fluorine fused welding flux.

2.Color:red brown to light yellow.

3.Grain size:of 8-40(2.5-0.45mm) and 14-40(1.5-0.45mm) meshes.

4.Current:alternating or direct current(welding wires must be connected with the positive electrode when direct current is used).

welding flux Usage:

1.for low-carbon and low-alloy steels like 16Mn and 15MnV, as well as ships, boilers and high-pressure vessels[applied to welding wires such as H08A(AWS EL8), H08MnA(AWS EM12) and H10MnSi(AWS EM13K)]

2.for electro-slag and copper welding.

Cautions:

1.The oil stain, moisture, iron rust and other impurities must be removed from the surface.

2.the welding Flux must be baked under 250~300°C for 2 hours before welding.

Chemical Composition:(%)

| AL2O3 +MnO | CaO+MgO | SiO2 | CaF2 | FeO | S ,P |

| 35~44 | 8~13 | 40~44 | 3~8 | ≤ 1.8 | ≤ 0.05 |

Mechanical Performance:Applied to H08A (AWS EL8)

| Test item | Yield strength 6s (Mpa) | Tensile strength 6b (Mpa) | Elongation δ5(%) | Impact absorption rate Akv (-20ºC)(J) |

| Common results | ≥400 | ≥550 | ≥22 | ≥34 |

Contact us if you need more details on Welding Flux. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Welding Material、Fused Flux. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Welding Flux. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Welding Material、Fused Flux. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Welding Flux

Premium Related Products

Other Products

Hot Products

Polyester Spiral Filter Cloth Made in ChinaWoven Fabric Dryer Mesh BeltPolyester / Nylon Silk Printing Screen Mesh/Belt/ ClothPolyester Forming Mesh BeltPolyeste Car Carpet Felt for CarWater Proof Oil-Proof Polyester Filter Bag for Air FilterationGeo Bag for Construction MaterialPE Water Saving Drip Irrigation Pipe with Round DrippersDouble Layer Geotextile Single Layer Geomembrane Compound GeomembranePet Composite Geotechnological Geomembrane FilmSubmerged Arc Welding Flux for Steel Structure (sj101)Woven 100% Cotton Grey FabricNon Woven Needle Punched Polyester Waterproof Geotextile MaterialNeedle Punch Double Color Jacquard Carpet for Exhibition CarpetWaterproof Anti-Slip Door Mat Carpe with PVC BackingPolyester Non-Woven Plain Red Exhition Carpet